Quick Fix: Broken Laundry Rack

My family uses this laundry rack all the time, so when the wind blew it over and cracked one of the top rails (rendering it surprisingly unstable, I’ll add), I realized I needed to repair or replace it quick. A few wraps of tape would be a fast solution but most likely be too floppy to be effective, so I thought about adding a sleeve that would hold both sides of the break together like a cast on a broken bone. I first considered using heat-shrink tubing, but then I realized I could quickly 3D print something that is designed for the exact size of the doweling. I love a good functional print.

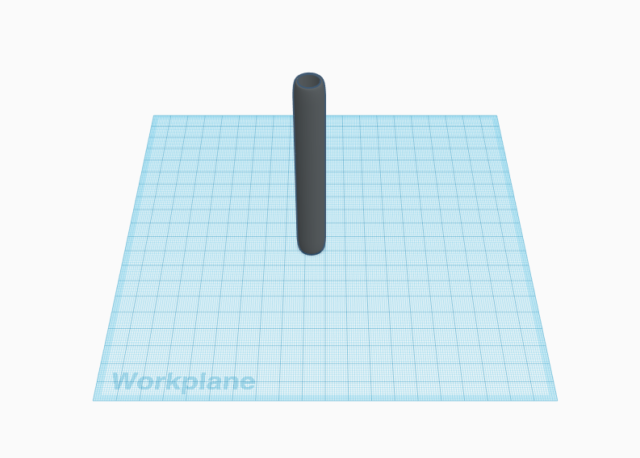

First, I measured the diameter of the broken rod with my digital calipers and bumped it up a tiny bit to give some wiggle room/allow for shrinkage. This is not uncommon with printing. I then knocked out a quick tube shape on Tinkercad with tapered edges to keep clothes from snagging. Final measurements were 10.2mm ID; 13.2mm OD; 100mm long.

The design process took a few minutes; printing was about 30.

Getting the sleeve onto the dowel required a bit of force and a bit of heat from the hot air gun — a trick that I find myself using pretty frequently with printing. Rather than throwing away an “almost-there” design, warm it up with some hot air and work it into place before it cools again. This saves me a lot of waste.

It seems to be holding strong now; the Nylon-X filament is pretty durable.

There are countless other ways to have fixed this but for the amount of effort and cost, I’m particularly happy. Luckily I had the tools to make this repair happen so quick. Now it hopefully doesn’t split along a layer line. If it does, I’ll update here.